Ourproducts / Coated Diamonds

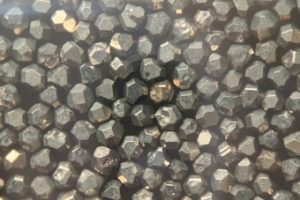

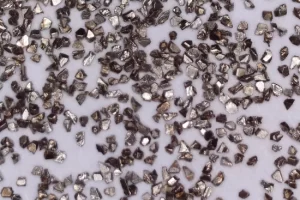

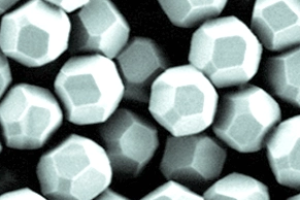

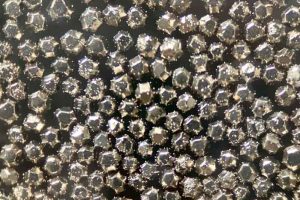

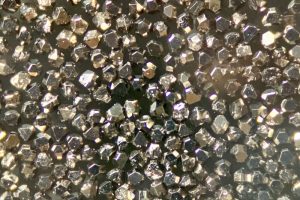

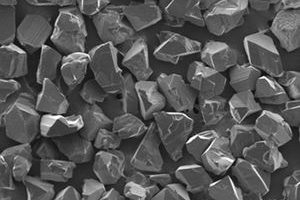

Coated Diamonds

Coated diamond powder refers to diamond particles that have been treated or coated with a thin layer of another material. This coating serves various purposes, enhancing the performance and versatility of diamond powder in different applications. The coating material is chosen based on the specific requirements of the intended use.

Ti COATING

Feature:

– Titanium as a kind of metal can improve heat dissipation and reduce heat damage thus protect the diamond.

– Decrease diamond particles graphitization and carbonization when sintering at high temperature. – Ti coating’s rough surface will enhance the mechanical retention between diamond and bond system, therefore improve the tool life.

Recommendation:

– Sintered Metal Bond Diamond Tools like saw blade, diamond segment,diamond wire saw beads.

TiC COATING

Feature:

– TiC layer when do the coating, thicker coating layer and weight than normal Ticoating, better performance than normal Ti coating

Recommendation:

– Sintered Metal Bond (Cobalt bond, Iron bond, Stannum, Bronze bond systems)Tools like premium diamond saw blade, diamond wire saw beads.

Si COATING

Feature:

– Silicon element could help avoid the corrosion from Fe element of the metal bond system, protect the diamond during sintering, prolong the tool life.

Recommendation:

– Sintered Metal Bond Diamond Tools at high temperature.

Ni COATING

Feature:

– Ti coating could improve the abrasion resistance and diamond tool’s cutting performance.

– Different type surface structures could select, flat and spiky type.

Recommendation:

– Sintered Metal Bond Diamond Tools like saw blade, diamond segment, wire saw beads.

Cr COATING

Feature:

– Chromium element could provide help diamond’s wettability and affinity during the tool’s producing, and preform the Cr carbide type first which improve the performance of the diamond tools with this type coated diamond.

Recommendation:

– Sintered Metal Bond Diamond Tools with Cobalt, Bronze based bond systems, Electroplated tools.

W(TUNGSTEN) COATING

Feature:

– W as a kind of refractory metals is difficult to coat with diamond particle, it will preform a chemical compound WC/W2C at the beginning of the coating process which could prominently enhance the retention between diamond particle and bond system.

Recommendation:

– Sintered Metal Bond Diamond Tools, Electroplated and Brazing diamond tools.

Co COATING

Feature:

– Cobalt coating can protect diamond particles from oxidation with the Co’s property itself.

Recommendation:

– For making high temperature sintered diamond tools and Vacumm brazing diamond tools.

Si+Ni COATING

Feature:

– Double metal layers coating provides a much better retention between the bond system and diamond particles which expand diamond tool life. – Higher Nickel weight percentage will need a less percentage of the of Ni the bond system.

Recommendation:

– Diamond cup wheel, saw blade, diamond segment, diamond wire saw beads.