CBN(Cubic Boron Nitride)

Description

- Good Self-sharpening

- Low toughness and thermal stability

- Irregular and angular shape

Applications

- Cutting Tools: CBN is widely used in the manufacturing of cutting tools for machining ferrous materials like hardened steels and cast iron.

- Grinding Wheels: CBN abrasive grains are used in grinding wheels for precision grinding operations.

- Turning and Milling: CBN inserts are employed in turning and milling operations, especially for hard materials.

- Bearings and Aerospace Components: CBN is utilized in the production of high-precision bearings and components for the aerospace industry due to its hardness and wear resistance.

- Hardened Steel Machining: CBN tools are particularly effective in machining hardened steels, where conventional tools may experience rapid wear.

- Tool and Die Making: CBN is employed in tool and die manufacturing where high precision and durability are crucial for producing intricate shapes and maintaining tolerances.

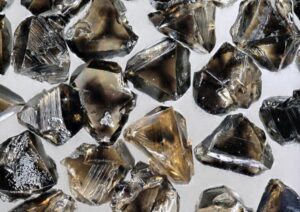

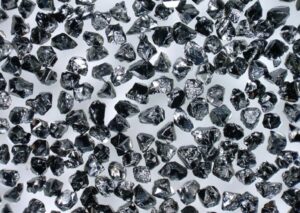

Black CBN

CBNB 10

CBNB 15

CBNB15 is a kind of black mono-crystal, with irregular shape, mediumstrength and good thermal stability, usually used for vitrified bondandresin bond tools. By using this material, the tool have the advantages of

good efficiency and no burning on work pieces when machiningwithhigh speed.

CBNB 20

CBNB20 is a kind of bright black mono-crystal, with irregular shape, high strength and good thermal stability, usually used for vitrifiedbondand metal bond tools.

CBNB 30

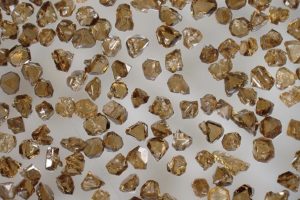

Amber CBN

CBNBA 10

CBNA10 is a kind amber mono-crystal, with irregular shape, goodtransparency and medium strength, usually used for resin bond tools withmedium tool using life

CBNBA 20

Brown CBN

CBNA40(C10)

CBNA40(C10) is a kind of dark brown mono-crystal, with irregular

shape, semi-transparency, high toughness and good thermal stability, usually used for vitrified and metal bond tools.

CBNA60(C20)

CBNA60(C20) is a kind of dark brown mono-crystal, with blockyshape, semi-transparency, high toughness and good thermal stability, usuallyused for vitrified and metal bond tools. By using this material, the toolshave the advantages of high adaptability, good self-sharp abilityandlonger tool life